In modern architectural and industrial design, doors are no longer just access points—they often serve as critical structural and aesthetic components. Especially in commercial buildings, factories, hospitals, or public venues, some doors are notably large, heavy, and subject to continuous use. This raises a key question: can Multi-Function Hydraulic Hinges perform reliably when installed on doors that are either exceptionally heavy or operated with extreme frequency?

The main appeal of Multi-Function Hydraulic Hinges lies in their ability to combine soft-closing, self-return, and adjustable tension within a single compact mechanism. These features make them ideal for typical residential or light commercial doors. However, as the application scope widens to include oversized entryways, metal-clad fire doors, or continuously cycled doors in public restrooms and airports, hinge durability and load capacity become much more critical.

The core challenge in such demanding scenarios is the mechanical stress exerted on the hinge components. Ultra-heavy doors, often weighing over 100 kilograms, impose significant shear and bending forces during each open-close cycle. If the hinge body, internal springs, or pivot pins are not engineered to withstand these loads, premature failure can occur, causing safety risks, structural damage, or inconsistent closing behavior.

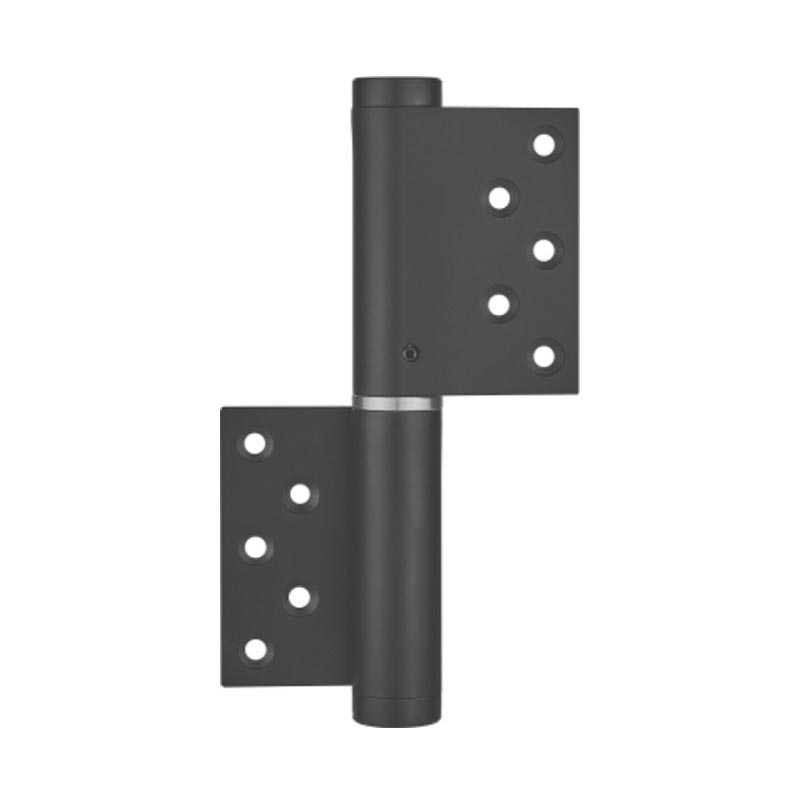

For this reason, not all Multi-Function Hydraulic Hinges are suitable for such use. However, some models are specifically designed and reinforced for high-load applications. These versions typically use solid forged bodies, reinforced mounting plates, and oversized hydraulic pistons that provide controlled damping even under immense weight. The mounting screws and door leaf interfaces are also reinforced to prevent deformation or loosening during long-term operation.

When it comes to high-frequency use—such as in commercial restrooms, office doors, or retail entrances—durability under wear is just as important as load capacity. Continuous movement accelerates wear on seals, pins, and fluid chambers. In high-end hydraulic hinges, manufacturers counteract this by using advanced materials such as tempered steel for internal springs, synthetic wear-resistant bushings, and specially formulated hydraulic fluids with thermal and chemical stability. These features allow the hinge to maintain performance over tens of thousands of cycles without significant degradation.

Another essential consideration is heat buildup. During rapid, repeated movement, the hydraulic fluid inside the hinge may heat up, altering its viscosity and therefore its damping behavior. Good hinges are equipped with temperature-stable oils and compensatory valve systems that ensure smooth, consistent motion regardless of ambient or operational heat levels.

Additionally, for oversized doors, hinge count and placement are critical. A single pair of hinges, even if heavy-duty, may not be sufficient. Engineers often use three or more hydraulic hinges distributed along the door edge to balance the load and reduce strain on individual hinges. Some systems combine hydraulic hinges with traditional bearing hinges to share the mechanical load while preserving damping functionality.

In conclusion, while not all Multi-Function Hydraulic Hinges are appropriate for ultra-heavy or high-frequency use, many purpose-built models are more than capable. The key lies in selecting the correct grade of hinge, installing it according to recommended practices, and understanding the environmental and operational demands of the application. With the right components and setup, these hinges can deliver both functionality and longevity in even the challenging door systems.