Understanding the Longevity of Damping Function in Spring Hinges

Damping spring hinges are widely valued for their ability to provide smooth, controlled, and silent door or cabinet closure. However, a frequently asked question from consumers and manufacturers alike is whether the damping function of these hinges remains consistent over time or gradually weakens due to regular use. This concern is valid, especially for installations where longevity, safety, and performance are critical. Understanding how these hinges are constructed and how they perform under stress is key to evaluating their long-term reliability.

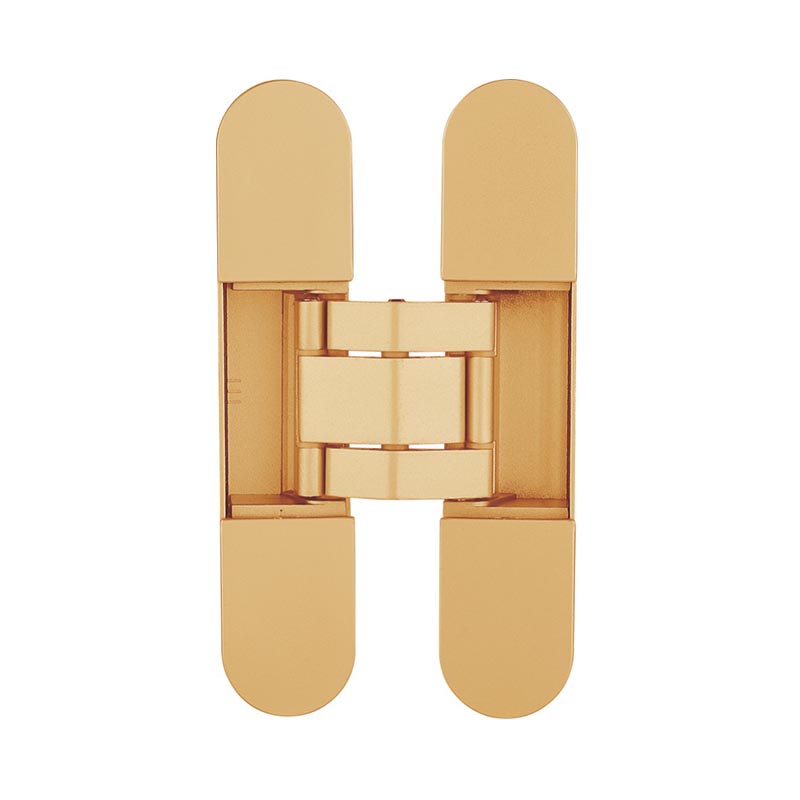

Material and Design Influence Performance Stability

The durability of the damping mechanism heavily depends on the materials used and the quality of engineering. High-quality damping spring hinges typically use silicone-based or oil-based dampers that are designed to resist degradation over time. These damping fluids or components are sealed within the hinge structure, protecting them from exposure to dust, air, or temperature fluctuations that could affect their viscosity and performance. The spring mechanism itself is usually made of stainless steel or other resilient alloys that can withstand tens of thousands of cycles without fatigue or failure.

Factors That May Cause Damping Degradation

While well-manufactured hinges are built to last, there are still scenarios where the damping function may degrade. Excessive exposure to extreme temperatures, particularly heat, can cause the damping fluid to thin or leak, resulting in less effective resistance during closure. Similarly, poor hinge installation or misalignment can cause uneven wear, which may reduce the effectiveness of the damping over time. In lower-quality products, inferior materials and inadequate sealing can allow dust and moisture to penetrate the damping chamber, compromising its performance.

Usage Frequency and Environmental Conditions

The frequency with which a hinge is used also plays a significant role in how long the damping function remains effective. In high-traffic environments such as commercial kitchens, public restrooms, or office furniture, damping spring hinges may be opened and closed hundreds of times daily. In such cases, even a premium hinge will eventually show some signs of wear. However, many products are tested to endure 50,000 to 100,000 cycles without significant loss in damping quality, assuming normal usage and proper installation.

Detecting and Responding to Damping Fatigue

Signs of weakening damping function include faster-than-usual door closure, noticeable noise during operation, or visible hinge misalignment. When detected early, these issues can often be resolved by minor adjustments or part replacements, especially in modular hinge systems. In some cases, a hinge replacement may be the effective solution. It's worth noting that for most residential and light-commercial applications, quality damping spring hinges will function reliably for many years before any noticeable performance loss occurs.

Maintenance and Longevity Optimization

To prolong the life of damping spring hinges, users should ensure proper installation, avoid slamming doors, and periodically check for dust buildup or misalignment. Although these hinges require little to no regular maintenance, maintaining a clean operating environment and avoiding exposure to corrosive substances can further enhance performance stability. For critical environments, selecting hinges with verified lifecycle testing and certifications is recommended to ensure long-term damping reliability.

Conclusion

While the damping function of damping spring hinges may gradually diminish under heavy use or harsh conditions, high-quality products are specifically designed to provide stable performance over extended periods. With proper use and minimal care, these hinges can maintain their soft-closing capabilities for many years. Choosing well-engineered models with proven endurance ratings remains the effective way to ensure consistent damping performance throughout the hinge’s lifespan.